Description

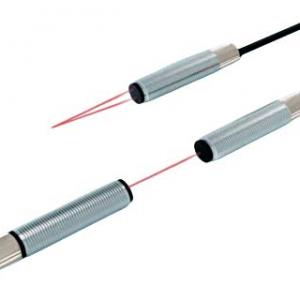

A1230 Mercury slip ring

Mercury slip ring use on any rotating object to transfer tiny voltage ,digital audio ,Gigabit Ethernet,HF signal, digital/analog video,sensor signal and so on.

Advantage

With the continuous development of the industrial industry, the degree of sophistication of industrial machinery is also increasing, and it has gradually evolved from the old-fashioned rough and rudimentary equipment to the sophisticated instruments that people see today, and some are more advanced. The industry has adopted relatively high-end industrial equipment and automated robots for production, and the appearance of the mercury slip ring is for these precision machinery. Although most of the slip rings compete with this product, the mercury slip ring The ring takes advantage of its special medium and compact structure to compare most of the slip nets, but the mercury slip ring is not only chosen by many industries because of these advantages, but also because it has In order to have a longer service life than other slip ring equipment, because the medium used inside the mercury slip ring is mercury characteristics, the equipment runs almost without wear, so it will have a longer service life than most equipment. , The slip rings generally used in industrial machinery and equipment need frequent rotation during operation. If the slip ring with a short service life is used for a period of time, it will fail. The mercury slip ring has several advantages. load of these industrial equipment.

It is because the mercury slip ring has the above advantages that it can get the choice of most industries when it competes with other industries. Although some customers still struggle with its price before choosing, the mercury slip ring product relies on Features such as maintenance-free, no noise, high speed and no noise, and high prices are also chosen by so many customers.

Benefits:

- Unique signal handling performance with minimal electrical circuit noise

- Very low electric noise

- Anti-jamming ,very low cost

- Very low contact resistance (Less than 1mΩ)

- No maintenance and better reliability than traditional sling rings

-

Suitable for signal and power transfer of rotating devices or instruments

|

Part no.

|

Poles

|

Current(A)

|

AC/DC(V)

|

MHZ

|

Contact Resistance

|

Max rotating speed

|

working temp.

|

torque

|

|

Max rpm

|

Max/Min ℃

|

(x10-3Nm)

|

||||||

|

A1H25S

|

1 pole

|

250

|

--

|

200

|

<1mΩ

|

1200

|

-29℃~60℃

|

250

|

|

A1H35S

|

1 pole

|

350

|

--

|

200

|

<1mΩ

|

800

|

-29℃~60℃

|

300

|

|

A1H25PS

|

1 pole

|

250

|

--

|

200

|

<1mΩ

|

1200

|

-29℃~60℃

|

250

|

|

A1H65PS

|

1 pole

|

650

|

--

|

200

|

<1mΩ

|

200

|

-29℃~60℃

|

1000

|

|

A1H150PS

|

1 pole

|

1500

|

--

|

200

|

<1mΩ

|

100

|

-29℃~60℃

|

2000

|

|

A2H

|

2 pole

|

30A

|

250

|

200

|

<1mΩ

|

1800

|

-29℃~60℃

|

200

|

|

A3H

|

3 pole

|

30A

|

250

|

200

|

<1mΩ

|

1200

|

-29℃~60℃

|

400

|

|

A4H

|

4 pole

|

30A/2+4A/2

|

250

|

200

|

<1mΩ

|

1200

|

-29℃~60℃

|

400

|

|

A6H

|

6 pole

|

30A/4+4A/2

|

250

|

100

|

<1mΩ

|

300

|

-29℃~60℃

|

700

|

|

A8H

|

8 pole

|

30A/4+4A/4

|

250

|

100

|

<1mΩ

|

200

|

-29℃~60℃

|

1000

|

|

A1030

|

10 pole

|

30A/8

|

250

|

100

|

<1mΩ

|

100

|

-29℃~60℃

|

1500

|

|

A1230

|

12 pole

|

30A/10+4A/2

|

250

|

100

|

<1mΩ

|

60

|

-29℃~60℃

|

2000

|

|

A1M

|

1 pole

|

10A

|

--

|

200

|

<1mΩ

|

3600

|

-29℃~60℃

|

35

|

|

A1M2

|

1 pole

|

20A

|

--

|

200

|

<1mΩ

|

2000

|

-29℃~60℃

|

50

|

|

A1M5

|

1 pole

|

50A

|

--

|

200

|

<1mΩ

|

1800

|

-29℃~60℃

|

70

|

|

A2S

|

2 pole

|

4A

|

250

|

200

|

<1mΩ

|

2000

|

-29℃~60℃

|

75

|

|

A3S

|

3 pole

|

4A

|

250

|

200

|

<1mΩ

|

1800

|

-29℃~60℃

|

100

|